Column ultrafiltration membrane

Ultrafiltration is based on the principle of sieving, similar to a very fine sieve. The pore size distribution of ultrafiltration membranes is very narrow, allowing water and solutes smaller than the membrane pore size to pass through at a certain pressure (0.1~0.6MPa), while preventing solutes larger than the membrane pore size from passing through. Using the pressure difference on both sides of the membrane as the driving pressure, filtration, separation, concentration, and purification of water and other feed liquids are achieved.

Product features of column ultrafiltration membrane:

1. Hollow fiber structure: The column ultrafiltration membrane fibers adopt a hollow fiber structure, and each hollow fiber has a hollow pipe inside. The membrane material with this structure has a high specific surface area, effectively increasing the contact area between the membrane and the solution, and improving the flux of the membrane.

2. PVDF membrane material: Column ultrafiltration membrane PVDF membrane fibers not only have excellent chemical resistance, but also have good anti pollution performance. PVDF membrane material has a small pore size and high retention rate, which can effectively intercept pollutants such as suspended particles, colloidal substances, and microorganisms in water, ensuring the cleanliness and safety of the effluent.

3. Internal and external pressure difference drive: The column ultrafiltration membrane uses the internal and external pressure difference to drive water flow through the membrane pores. Applying high pressure outside the membrane allows water molecules and small solute molecules to pass through the membrane pores, while large molecules and pollutants are retained on the membrane surface to form a concentrated solution. Through this method, impurities in water are effectively separated, achieving purification and separation of water.

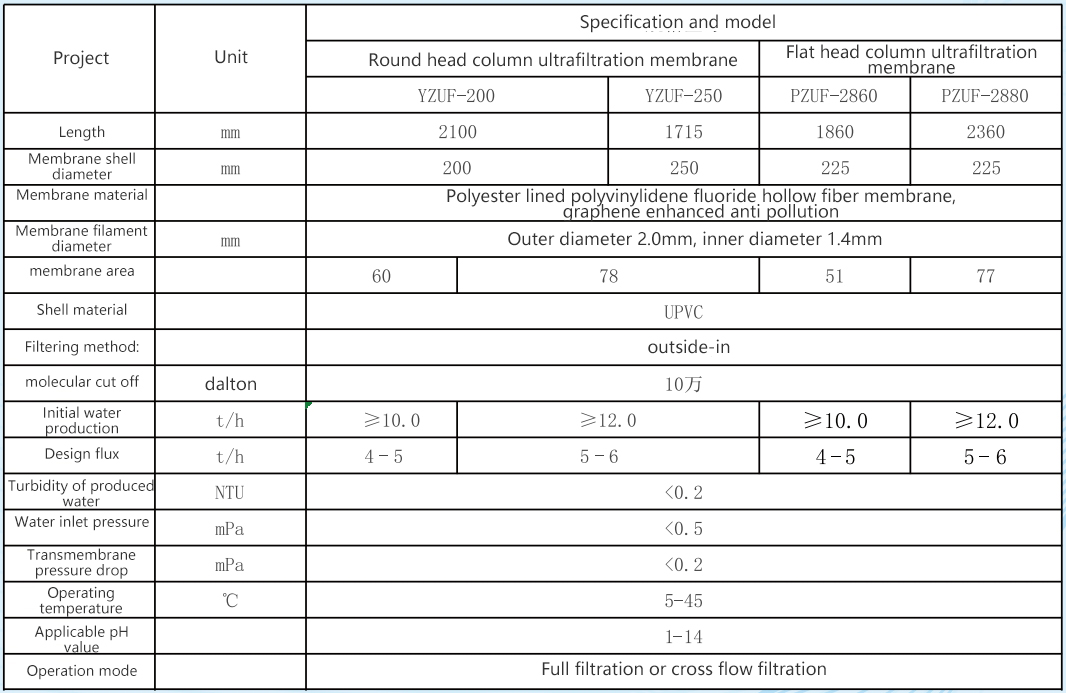

Product specifications:

Application areas:

1. Surface water purification. The pore size of ultrafiltration membrane is very small, only 2-50 nanometers, which can effectively block suspended solids, particles, bacteria and other small substances in surface water, thereby improving the purification effect of water.

2. Drinking water filtration. The combination of ultrafiltration membrane, nanofiltration membrane, and reverse osmosis membrane is used for drinking water treatment in households, municipalities, enterprises, and other units to obtain clean and safe drinking water.

3. Industrial process water treatment. For municipal water supply, a combination of ultrafiltration and reverse osmosis processes is used to remove inorganic salts and prepare purified water, which is widely used as industrial process water in power plants, electronics, chips, energy, chemical, pharmaceutical, food and other fields.

4. Wastewater treatment. Ultrafiltration membranes are used for industrial wastewater treatment in municipal wastewater treatment plants, biopharmaceuticals, and chemical enterprises. They can remove impurities such as particulate matter, colloids, and organic matter, and improve the effectiveness of wastewater treatment.

5. Municipal sewage treatment. Ultrafiltration membrane is applied in the upgrading and transformation of municipal sewage treatment, the preparation of regenerated water, and the treatment of water ecological environment.

6. Industrial wastewater treatment. After biochemical treatment of industrial wastewater, the combined process of ultrafiltration and reverse osmosis can effectively remove pollution sources, achieve water resource recycling and zero discharge of wastewater.

matters needing attention:

Ultrafiltration membranes are fine, porous polymer materials that are prone to pore blockage and membrane fouling. Therefore, the ultrafiltration process must have necessary pretreatment (generally 50-100um filtration accuracy) to reduce fouling and blockage of the ultrafiltration membrane and extend its lifespan. The hollow fiber ultrafiltration membrane module adopts full flow filtration and requires regular opening of the discharge valve. Adopting cross flow filtration requires opening the drain valve to discharge 5% -10% concentrated water. The operation of hollow fiber membrane ultrafiltration membrane requires timed backwashing, which involves introducing product water from the production side to the inlet side to restore the membrane pores and remove pollutants attached to the membrane surface.