Roll type ultrafiltration membrane

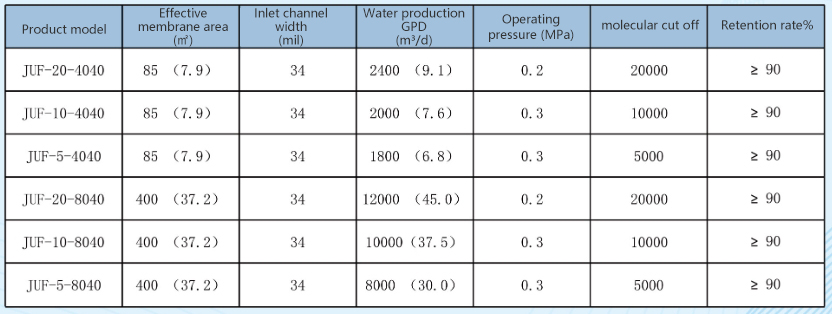

1. The test data is based on the following test conditions: the test solution is a 1000 ppm polyethylene glycol aqueous solution, at 25 ° C, pH 7.5, The system recovery rate is 15%. The molecular weights of polyethylene glycol are 200000, 10000, and 5000, respectively.

2. The water production and molecular weight cut-off of the roll type ultrafiltration membrane are the average values, and the error of the water production of a single membrane element is within 10%.

3. The roll type ultrafiltration membrane module can also use a 47mil grid according to customer requirements.

As a sophisticated membrane separation technology, roll ultrafiltration membranes have the following technical advantages

1. The pore size is small and the pore size distribution is dense, which can fully intercept substances with a particle size approximately the size of the ultrafiltration membrane in the material.

2. It has good anti pollution ability and a smooth surface of the roll type ultrafiltration membrane, which can achieve material cross flow filtration while ensuring a large flow rate and avoiding impurity blockage.

3. Easy to operate, only relying on pressure driven filtration process, without the need for high-temperature heating sterilization and chemical reagent adsorption of impurities. It can effectively retain the active ingredients in the material without any quality changes or environmental pollution caused by wastewater.

4. Small footprint, high degree of automation, low energy consumption, and low overall investment cost.

Application areas:

Roll up ultrafiltration membrane is a membrane separation technology with excellent technical design, widely used in fields such as food industry, biopharmaceuticals, natural product extraction, and wastewater resource utilization.

1. After filtration through a roll type ultrafiltration membrane, the fruit juice has a high concentration of nutrients, good flavor, and guaranteed hygiene and safety. It is not easy to spoil or precipitate, has a longer shelf life, and improves economic efficiency.

2. Microbial fermentation product extraction. Microbial fermentation products such as antibiotics, vitamins, amino acids, etc. require rapid separation of microbial cells, proteins, pigments, etc. from the target products. By using a roll type ultrafiltration membrane, microorganisms can be efficiently removed and the target product can be filtered through the fermentation broth. The roll type ultrafiltration membrane process operates stably, with low energy consumption and high product purity.

3. Food and beverage separation and purification. Separation and purification of oligosaccharides and starch sugars, decolorization of monosodium glutamate neutralizing solution, clarification and decolorization of beverages, etc.

4. Reuse of electrophoretic paint wastewater. The automotive and instrument industries adopt electrophoretic paint coating, and the use of roll type ultrafiltration membranes can recycle electrophoretic paint and reuse water to improve economic efficiency.

5. Wastewater treatment and resource utilization. Roll up ultrafiltration membrane is used for sewage purification treatment, with high permeation flux, strong anti pollution ability, and good operational stability. The combination process of roll type ultrafiltration membrane, nanofiltration membrane, and reverse osmosis membrane is used for wastewater resource utilization and can operate stably for a long period of time.