Industrial reverse osmosis membrane

Reverse osmosis (RO) is a membrane separation technology developed in the 1960s. Under pressure, most solutes in water are intercepted by reverse osmosis membranes, and only water molecules pass through the separation process. The pore size of reverse osmosis membranes is as small as the nanometer level (1 nanometer=10-9 meters). Water molecules can pass through the R0 membrane, while impurities such as inorganic salts, heavy metal ions, organic matter, colloids, and bacteria in water cannot pass through the RO membrane, thus obtaining pure water. Reverse osmosis membrane separation technology, as the most energy-efficient and efficient water purification technology, has been widely used in fields such as drinking water, power plants, chemicals, pharmaceuticals, food, beverages, and seawater desalination.

Shandong Jinyu Membrane Technology Development Co., Ltd. has a fully automatic reverse osmosis membrane production line and packaging line, relying on precise and mature process control and scientific and meticulous production management to ensure industry-leading performance such as flux and desalination rate of reverse osmosis membrane components.

Reverse osmosis membrane components have the following advantages:

1. High throughput: Select non-woven fabric and polysulfone, control coating parameters, optimize separation functional layer structure, increase specific surface area, and achieve high throughput.

2. High desalination: Optimized raw materials and formulas, refined post-treatment processes, improved crosslinking degree of polyamide separation functional layer, achieve high desalination rate.

3. Anti pollution: By designing and regulating the microstructure of reverse osmosis membranes, the adsorption and retention of pollutants are effectively reduced, and the anti pollution ability is improved.

4. Stability: Excellent mechanical and chemical stability ensure the pressure resistance and acid alkali resistance of the reverse osmosis membrane, improving its service life.

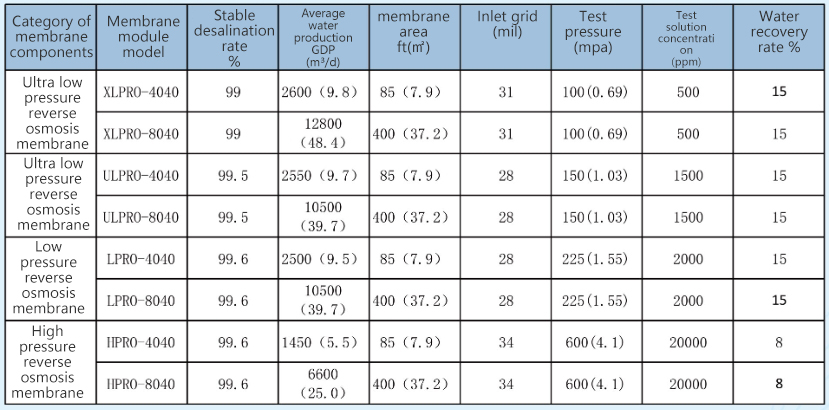

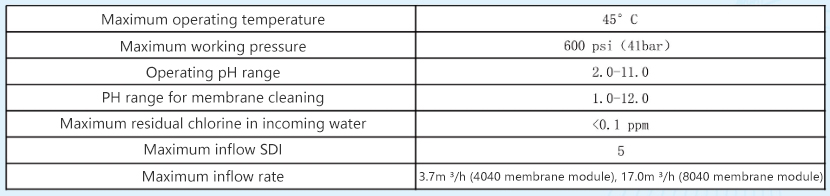

Product specifications:

1. The water production and desalination rate of the reverse osmosis membrane module are the average values, and the error of the water production of a single membrane module is within 10%.

2. The recommended maximum operating pressure for low-pressure reverse osmosis membrane components is 4.0 MPa. Choose high-pressure reverse osmosis membrane for higher usage pressure.

Ultra low pressure roll type reverse osmosis membrane module (XLPRO) product features: operates at extremely low pressure (0.69 MPa), with high desalination rate and low energy consumption. Suitable for the preparation of purified water from municipal tap water, surface water, etc. with a salt content below 500 ppm.

Ultra low pressure roll type reverse osmosis membrane module (ULPRO) product features: low operating pressure (1.03 MPa), high desalination rate, and low energy consumption. Suitable for the preparation of purified water from municipal tap water, groundwater, surface water, etc. with a salt content below 2000 ppm.

Low pressure roll type reverse osmosis membrane module (LPRO) product features: stable operation, energy saving, suitable for the preparation of purified water in surface water, brackish water, and other areas with salt content below 8000ppm. Characteristics of high-pressure roll type reverse osmosis membrane products: stable operation, energy saving. Suitable for desalination fields such as high salt water, brackish water, and seawater with a salt content of 20000-50000ppm. Generally, a two-stage membrane desalination process consisting of high-pressure reverse osmosis membrane and low-pressure reverse osmosis membrane is used to prepare purified water.

Maintenance and upkeep:

After a period of normal operation, reverse osmosis membrane components will be contaminated by suspended or insoluble substances in the feedwater. When the system performance decreases by 10% under standard conditions, or when scaling and fouling are clearly occurring, it should be cleaned in a timely manner.

2. Regular water flushing and chemical cleaning can restore the performance of reverse osmosis membrane components and extend their service life.

During the short-term shutdown period, the system should be flushed every 5 days, and the valves should be closed after flushing to prevent scaling and blockage.

4. If the system is shut down for a long time (more than 30 days), add 1% sodium bisulfite solution to prevent bacterial growth.