MBR membrane module

Release time:2025-04-14

Click:

The MBR curtain membrane module of Shandong Jinyu Membrane Technology Development Co., Ltd. uses polyvinylidene fluoride (PVDF) as the membrane separation functional layer, which is resistant to acid, alkali, and oxidation. Using polyester lining composite reinforcement technology, the tensile strength of the film filament is greater than 200N. The company has developed infiltration embedded coating technology, which results in uniform polyvinylidene chloride coating, improved porosity, and increased adhesion Add. We have developed a new formula reinforced with graphene, which has stable MBR membrane fiber structure, high hydrophilicity and porosity, high permeation flux, and strong anti pollution ability. Shandong Jinyu Membrane Technology Development Co., Ltd. carefully seals MBR curtain membranes with epoxy adhesive and polyurethane adhesive. Each curtain type membrane component undergoes airtightness testing to ensure compliance with industry standards. By relying on the efficient interception effect of MBR curtain membrane, high concentration microorganisms are retained in anaerobic and aerobic tanks, greatly improving sewage treatment efficiency, reducing COD and ammonia nitrogen in effluent, and improving the water quality of produced water. MBR curtain membrane modules are suitable for small-scale urban sewage treatment, large-scale municipal and park sewage treatment, industrial enterprise sewage treatment, as well as high difficulty organic wastewater treatment in coal chemical, petrochemical, pharmaceutical and other industries.

MBR curtain membrane product features:

1. Separation functional layer made of polyvinylidene fluoride (PVDF) material, resistant to acid, alkali, and oxidation

2. Graphene reinforcement enhances the hydrophilicity and anti fouling ability of MBR membrane fibers

3. Polyester lining increases MBR membrane filament strength, tensile resistance, and continuous filament

4. Penetrating embedded coating method, with strong adhesion between the skin and lining, wear-resistant and non peeling

5. MBR curtain type membrane root soft rubber protection reduces membrane fiber root wear and has a longer service life

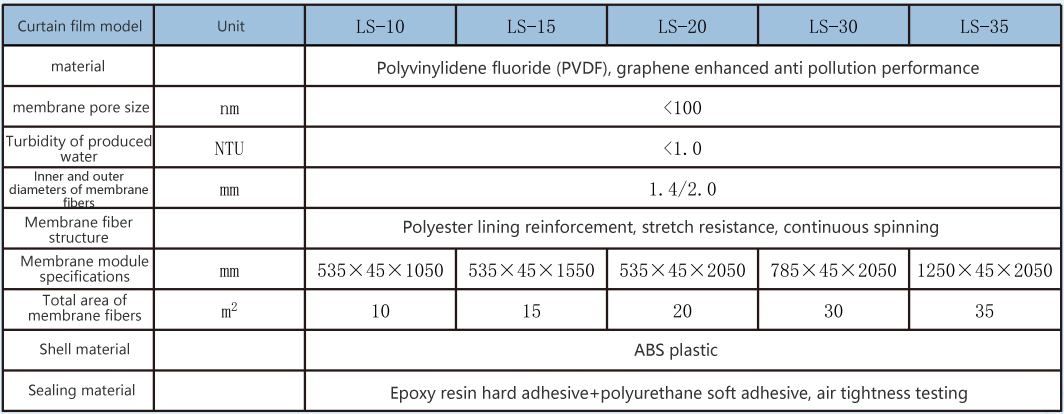

Product specifications:

Other specifications of MBR membrane modules can also be provided according to customer needs

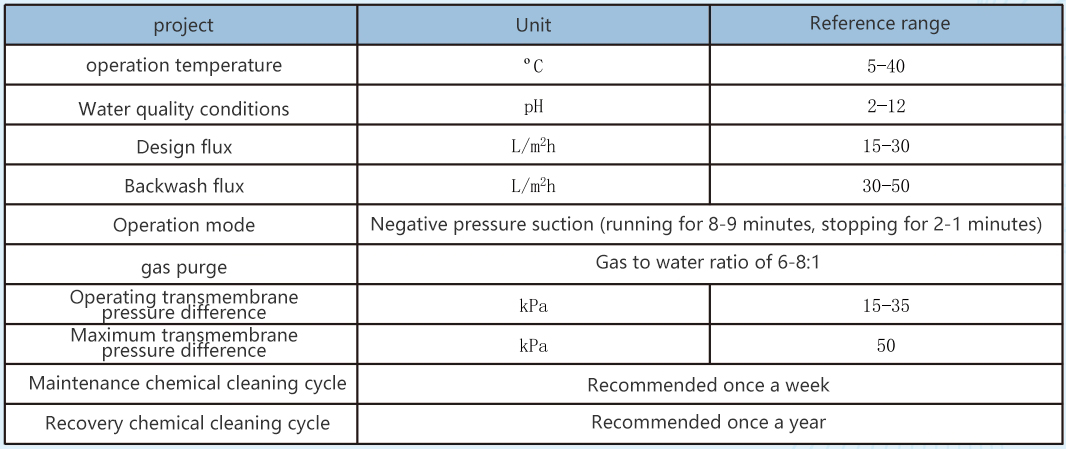

Operating conditions:

The chemical cleaning cycle is related to temperature, water quality, microorganisms, pollutants, etc. When the flux of MBR membrane is 20% lower than the design flux, perform maintenance chemical cleaning in a timely manner.

When the flux of MBR membrane is lower than 30% of the design flux, perform restorative chemical cleaning in a timely manner.