Nanofiltration membrane module

Nanofiltration (NF) is a membrane separation technology that falls between ultrafiltration and reverse osmosis. The membrane pore size is less than 2 nanometers, and it has a high retention rate for most organic compounds and multivalent salt ions in water, while the retention rate for monovalent ions is relatively low. Therefore, it has good selectivity and separation for monovalent multivalent salts. Nanofiltration membranes can separate and concentrate organic water-soluble molecules such as glucose and sucrose, and can be used for deep treatment of wastewater, pretreatment of seawater desalination, and separation of divalent ions for zero discharge of wastewater. Shandong Jinyu Membrane Technology Development Co., Ltd.'s nanofiltration membrane uses polyamide as the separation functional layer. The thickness of the separation functional layer is controllable, the pore size distribution is narrow, and the hydrophilicity is good. The nanofiltration membrane has a smooth surface, strong anti fouling ability, high permeation flux, and low operating energy consumption. Based on the different retention rates of monovalent ions, a series of nanofiltration membrane module products with NaCl removal rates of 30%, 50%, 70%, 90%, etc. have been developed to provide suitable solutions according to the actual needs of customers, in order to achieve the optimal process of nanofiltration membrane separation design.

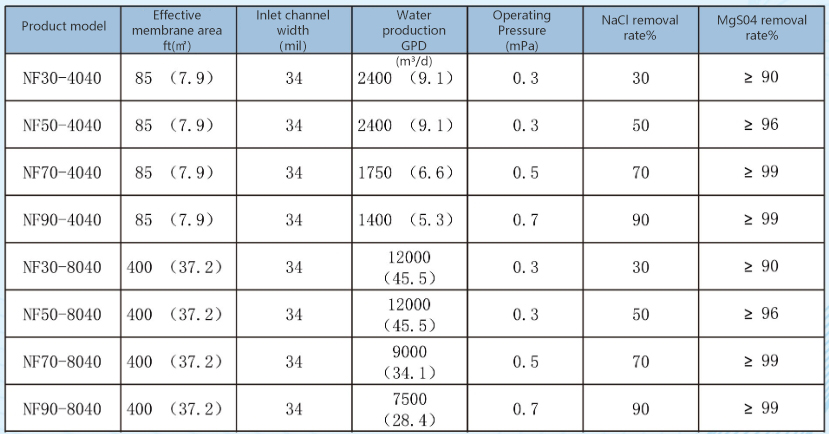

Product specifications:

1. The test data is based on the following test conditions: the test solution is a 2000 ppm NaCl aqueous solution, a 1000 ppm MgO: aqueous solution, at 25 ° C, pH7.5, The system recovery rate is 15%.

2. The water production and desalination rate of the nanofiltration membrane module are the average values, and the error of the water production of a single membrane module is within 10%.

3. The recommended maximum operating pressure for nanofiltration membrane components is 4.0 MPa. Consult in advance for higher usage pressure.

As a sophisticated membrane separation technology, nanofiltration membrane separation technology has the following advantages:

The nanofiltration concentration and purification process is carried out at room temperature, without phase change, chemical reaction, or introduction of other impurities, making it particularly suitable for thermosensitive substances.

2. Nanofiltration membrane separation can remove salt from products, reduce ash content, improve product purity, and improve product quality.

3. The nanofiltration membrane separation process has a high material recovery rate and minimal losses.

4. Nanofiltration membrane separation can recover useful substances such as acids, bases, alcohols, etc. in the solution, achieving the recycling of resources.

5. Introduction to the structure of nanofiltration equipment: Compact, small footprint, and low energy consumption.

6. Nanofiltration is easy to operate, can achieve automated operations, has good stability, and is easy to maintain.

Application areas:

1. Groundwater hardness reduction. NF-30 and NF-50 nanofiltration membranes can be selected, with high permeate flux, low water production energy consumption, and high hardness removal rate.

2. Surface water removes organic matter and color. NF-30 and NF-50 nanofiltration membranes can be selected, with high permeate flux, low water production energy consumption, high organic matter removal rate and chromaticity removal rate.

3. Processes such as oil-water separation, printing and dyeing wastewater, and leachate from garbage require deep removal of COD. NF-30 and NF-50 nanofiltration membranes can be selected, with high permeate flux, high COD removal rate, and low water production energy consumption.

4. Concentrate, separate, and recover glucose, fructose, and other substances. NF-50 and NF-70 nanofiltration membranes can be selected, with high permeation flux and high efficiency in concentration, separation, and recovery of glucose and other substances.

5. Recovery of heavy metal ions in metallurgical industries such as copper sulfate. NF-50 and NF-70 nanofiltration membranes can be selected, with high permeate flux, low water production energy consumption, and high metal ion recovery rate.

6. Organic and inorganic liquid purification treatment. To remove impurities from methanol and ethanol solutions and purify the solution, NF-50 and NF-70 nanofiltration membranes can be selected, which have high permeation flux, low water production energy consumption, and good purification effect.

7. Purification, concentration, and desalination of dyes. NF-30 and NF-50 nanofiltration membranes can be selected, with high permeate flux, low water production energy consumption, high dye concentration ratio, and low permeate loss.

8. Separation and concentration of natural medicines. NF-50, NF-70, and NF-90 nanofiltration membranes can be selected based on the molecular weight of the intercepted drug, with high permeation flux and low energy consumption for separation and concentration.

9. Concentrate the fermentation broth. NF-30 and NF-50 nanofiltration membranes are available for selection, with high permeate flux, low concentration energy consumption, and high operational stability.

10. Wastewater treatment in petrochemical, refining, and coal chemical industries. NF-30 and NF-50 nanofiltration membranes can be selected, with high permeate flux, low water production energy consumption, strong anti pollution ability, and high operational stability.

11. Separation of divalent ions in inorganic salts. NF-50 can be chosen for the separation of inorganic salt divalent anions, and NF-70 nanofiltration membrane can be chosen for the separation of inorganic salt divalent cations. It has low operating energy consumption and high separation factor for divalent ions.

12. Separation and concentration of small molecule organic compounds such as isopropanol. NF-90 nanofiltration membrane can be used for the separation and concentration of small organic molecules with a molecular weight of 100-150. Nanofiltration separation has high efficiency, low energy consumption, and high operational stability.